When culturing and growing mammalian cells, everything utilized in the process must remain sterile to prevent contamination.

Dedicated rooms and laminar flow biosafety cabinets help create a sterile environment, while frequent spraying of 70% ETOH on equipment and exposed surfaces adds another layer of protection.

How does one make sure the media used for growing cells is sterile?

While bottles of cell culture media arrive pre-sterilized from the manufacturer, once opened, and once additives like antibiotics are added, there is increased risk for contamination.

There are two ways to sterilize cell culture media or other lab buffers and solutions.

Liquids can be placed in a glass, or sturdy polypropylene, storage bottle and autoclaved for 15-20 min at 121C to destroy any living organism.

Because autoclaves are costly and not always available, an affordable alternative is to sterilize the cell culture media by filtering it with a membrane designed to trap organisms and impurities.

This membrane has pores that are no larger than 22 microns (10 microns is used to eliminate mycoplasma contamination).

A vacuum filter system incorporates vacuum force to sterilize media.

A vacuum filter system is made of three parts:

- An upper cup where the media is poured on top of the filtering membrane

- A receiving cup where the sterilized media is collected

- A “neck” with a barbed connector to attach the filter system to a vacuum pump or an in-house vacuum.

The vacuum forces the media through the membrane at the base of the upper cup down into the receiving cup below.

These are four critical features of a quality vacuum filtration system.

The vacuum filter upper cup and receiving bottle should be graduated:

Because cell culture media is frequently blended with antibiotics or growth agents, graduation lines indicate the total liquid volume to be sterilized.

Graduation lines on the receiving bottle indicate how much media is available, or remains, to be used for seeding and growing cells.

The vacuum filter system has a “stepped” connection barb:

A connection barb with varying width accommodates a wider range of tube diameters to ensure a proper seal and powerful suction force.

The vacuum filter system needs to be designed for near hands-free operation:

Depending on how much cellular debris is mixed into the media, it can take several minutes to sterilize the cell culture media.

When pouring the cell culture media into the upper cup, it is advisable to support the vacuum filter system base with the other hand, but once the media is being filtered, the lab technician should be able to walk away.

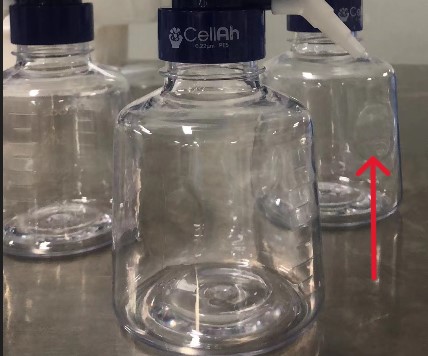

The vacuum filter system needs to be designed with a broad receiving bottle base and a low center of gravity to prevent it from tipping over.

The receiving bottle should also have indented hand-grips making it easy to transport the bottle, even with wet hands.

Vacuum filter systems with a neck diameter of 45mm can be screwed atop any GL45 glass bottle if the lab prefers that to using the enclosed receiving bottle.

The vacuum filter system membrane should be designed for fast sterilizing:

Two factors contribute to fast sterilizing of cell culture media:

The filter membrane is made from a low protein binding material, and the membrane diameter.

Vacuum filter systems used for sterilizing cell culture media are commonly made from PES (Polyethersulfone) but can also be made from nylon, PTFE, cellulose esters, PVDF or glass fibers.

Wide filtration membranes have more surface area to sterilize the media and get the job done quicker.

Currently, vacuum filtration system membranes with a 90mm diameter are the widest available.

When the media is loaded with cell debris, it is advisable to add an additional pre-filter membrane to capture this material and prevent the sterilizing membrane from clogging or slowing down.

Stellar Scientific’s CellAh family of vacuum filter systems meet and exceed these expectations.

CellAh vacuum filter systems are available in 250mL, 500mL and 1L sizes.