The Hows and Whys of Large Scale Cell Culture Production

Brand new to large scale cell culture production? Read this article for a refresher on cell culture principles and discussion of the scaling up process and related products.

You probably know that successful cell culture relies on the doubling and passage of cells after they have been plated.

Whether or not this happens depends mainly on the initial plating density and the success of the other culture conditions that you selected like temperature and nutrition.

Given the fact that cells can grow fast after plating, choosing a container of an intermediate size is usually pragmatic.

The goal is to achieve 80% confluency, meaning that about 80% of the container is occupied by cells, after 2-3 days of plating.

Once that has been achieved, the cultures are expanded in new containers.

Adherent vs. Suspension Cultures

Adherent cells are normally grown in a layer along one or several container surfaces, and suspension cells grow in media.

The primary difference between the two culture types is how to expand cultures, with adherent cells generally being more challenging.

Adherent cells are scraped from container surfaces or the attachments are chemically digested with the enzyme trypsin.

Both types are then centrifuged into pellets and old chemicals and media are poured away before they can be resuspended and expanded to new containers.

If you are working with adherent cells, scaling up your cultures requires you to think in terms of the available surfaces in the container that cells will grow on.

Different Container Types

Traditionally, starter cultures are plated in 25 mm flasks or 100 mm plates. These provide a good ratio of surface area to media volume for adherent cells.

Nonadherent cells will also need room for doubling, so the same containers can be used.

Here is where it gets a little tricky. Scaling up from this point may require troubleshooting and patience.

It’s easy to go from one 100 mm dish to two, but going from a 100 mm to two 150 mm dishes is not.

Methods for Expanding Cultures

One common alternative is to begin splitting cultures unevenly… scale half down and half up. Eventually you are expanding the larger containers.

However, if you choose to continue expanding the larger volume cultures, you may run into issues with space and handling.

Other newer container types have begun cropping up as solutions for the surface area to laboratory space dilemma.

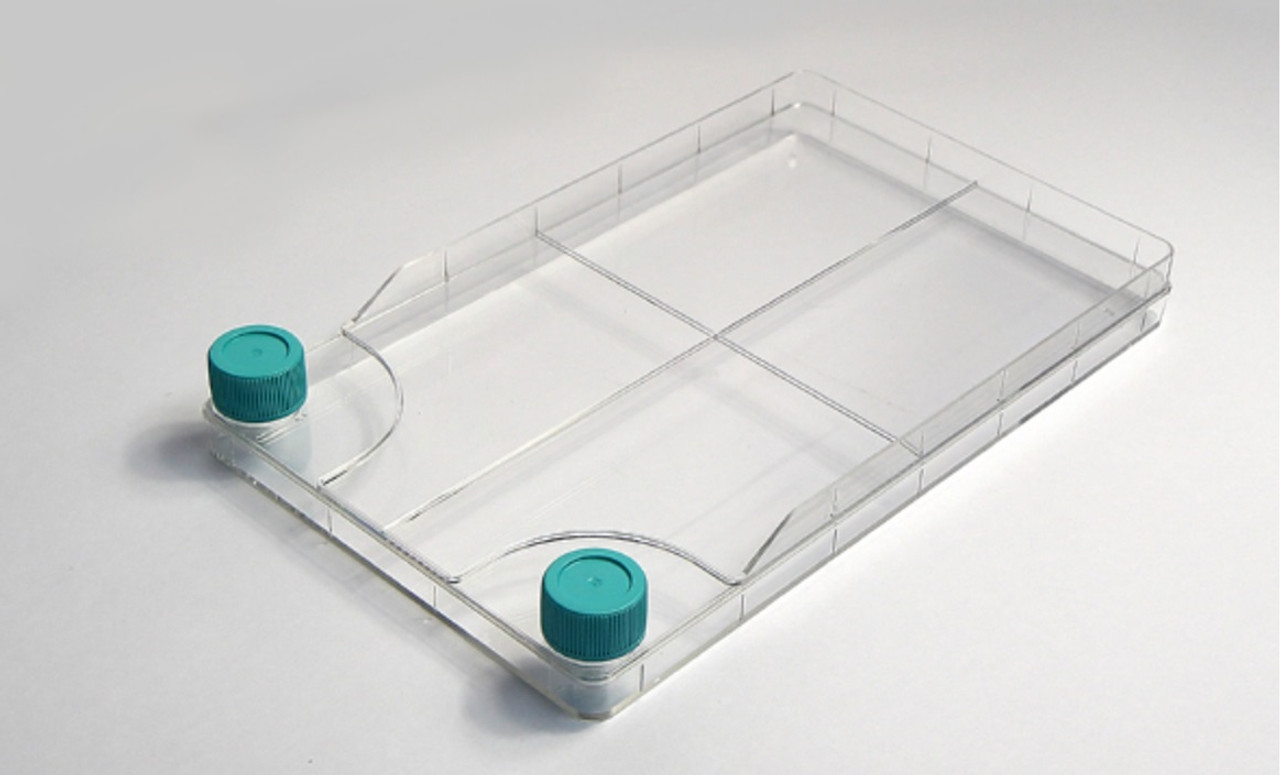

These are biofactories, short, flat, large surface-area culture containers for growing cells.

Multilayer biofactory flasks and stackable biofactories are a quintessential tool in any lab that requires large scale production of monolayer cultures.

Pros of Biofactories

- Saves incubator space

- Saves media

- Enhances surface area

- Stackable

- Easier to aerate cultures

Biofactories provide large amounts of surface area. The area ranges from 647 cm2 to over 6,000 cm2 per factory.

Why Use Large Scale Cell Cultures?

The use of larger scale cell cultures may seem extravagant and silly to those who are used to using smaller formats, but it’s sometimes required.

Large scale cultures are crucial for monoclonal antibody production.

Types of Bioreactors

Large scale industrial bioreactors are used in the early parts of the engineering process. Different types of bioreactors are used depending on the application.

Most cell culture processes require bioreactors that are good at aerating contents. You can view a list of different industrial bioreactors here.

Antibody Production

For commercial antibody production, cell lines are engineered to produce the antibody of interest.

A screening process that selects the clones that produce the highest antibody titers are scaled up and carrier forward.

Commercial production and research laboratory production differ in scale, but both will use bioreactor style containers for top producing clones.

Why Does Monoclonal Antibody Production Use Bioreactors?

Because monoclonal antibody production calls for large numbers of similar cells, it is too costly and labor intensive to manual culture for these protocols

Industrial bioreactors cut down on the use of materials like plates and flasks and reduce manual labor. Some workflows are entirely automated.

Once it is time to produce antibody serum from cultures, cells are expanded into slightly smaller scale biofactor chambers.

See these biofactory 1 chamber containers developed specifically for noncommercial laboratory development of monoclonal antibodies.

Industrial Bioreactors used for Mammalian Cell Culture

| Name | Advantage | Disadvantage |

| Airlift Bubble Reactor | Efficient | Expensive |

| Continuous Stirred Tank | Temperature Control | Energy Costly |

See more on types of industrial bioreactors at Atlas Scientific.

Stem Cell Technology

Pluripotent stem cells that are engineered for use as donor tissue are grown in large scale batches.

Like cells engineered for monoclonal antibody production, they go through a growth and screening process before being scaled up.

Stellar Biofactories for Large Scale Cell Culture Production

At Stellar Scientific, we carry the latest innovations in large scale cell culture production. Visit our catalog to see the Nest line of multilayer biofactory containers.

We offer biofactories with as many as 10 layers for space efficient large scale production of monolayer cell cultures.

Just starting out with larger scale cell culture work? Start with something simple like this one layer, single chamber biofactory.

Maybe a biofactory isn’t what you need and you just want more lifelike tissue cultures?

Consider reading our article on 3D scaffolding for cell culture and check out our perfusion systems and scaffolding options.

As always, feel free to reach out to us with any questions through our contact us page!

Footnotes:

___________________

- “6 Types of Bioreactors.” Atlas Scientific, 22 May 2023, atlas-scientific.com/blog/types-of-bioreactors.

- Lee, B., Jung, S., Hashimura, Y., Lee, M., Borys, B. S., Dang, T., Kallos, M. S., Rodrigues, C. A. V., Silva, T. P., & Cabral, J. M. S. (2022). Cell Culture Process Scale-Up Challenges for Commercial-Scale Manufacturing of Allogeneic Pluripotent Stem Cell Products. Bioengineering (Basel, Switzerland), 9(3), 92. https://doi.org/10.3390/bioengineering9030092

- Li, F., Vijayasankaran, N., Shen, A. Y., Kiss, R., & Amanullah, A. (2010). Cell culture processes for monoclonal antibody production. mAbs, 2(5), 466–479. https://doi.org/10.4161/mabs.2.5.12720

- Segeritz, C. P., & Vallier, L. (2017). Cell Culture: Growing Cells as Model Systems In Vitro. Basic Science Methods for Clinical Researchers, 151–172. https://doi.org/10.1016/B978-0-12-803077-6.00009-6